BSC researchers participating in the knowlEdge project are helping to ensure that European industry is fit for the digital age by identifying weak points in traditional manufacturing processes and providing industry stakeholders with insights into how technology can improve operations and production. By incorporating artificial intelligence (AI) and high performance computing (HPC) into manufacturing, the project actively contributes to providing solutions that allow industry to adapt to the green and digital transition.

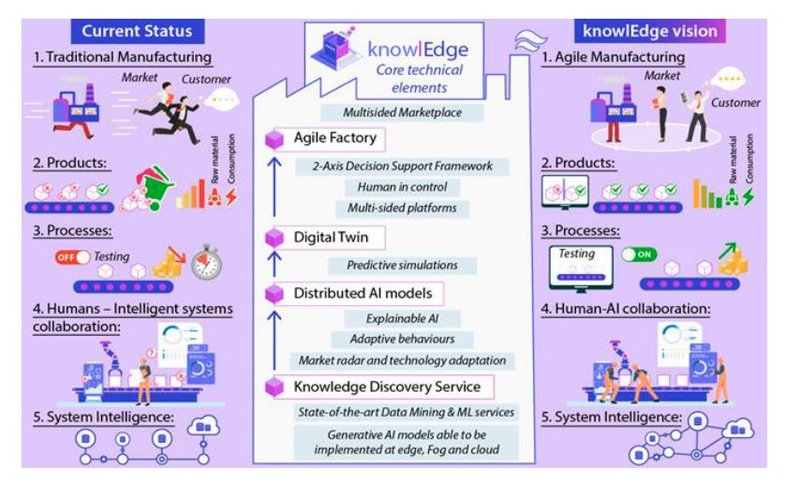

The BSC and members of this 12-partner consortium argue that despite the growing presence of AI and HPC in industry, a lack of uptake of new technology remains a challenge due to insufficient understanding, skills, or trust. To tackle this challenge, the project seeks to develop a new generation of AI models and data management tools, and combine them with technologies, tools and services (digital twin, decision support systems, etc.) that use HPC to help people make decisions, collaborate better with AI systems, and to fuse (human-AI) knowledge to allow for dynamic responses to changes in technology, materials, and customer preference. It also focuses on ensuring that the resulting simulations and visualizations are useful and understandable for decision-makers and industry leaders. Expected project results are illustrated in Figure 1 (below).

Marta Barroso Isidoro, the BSC´s new principal investigator for the knowlEdge project, emphasizes that, ‘The difficulty of integrating distributed data extraction and AI-based analytic capabilities into various types of industrial environments hinders their adoption in the manufacturing sector. As a result, there is an urgent need to develop automated AI solutions capable of efficiently utilizing data and providing insight, knowledge, or decision support at various levels of the compute continuum’.

BSC researchers are focusing on addressing stakeholder concerns about sensitive data and privacy and is leading the integration of Federated Learning (FL) and Auto Machine Learning (AutoML) for the use of a diverse set of machine-learning frameworks to solve the different needs of the client settings of each use case. Federated learning allows shared prediction model to be learned collaboratively while maintaining the training data on the client device, thus effectively isolating the need of storing data from developing machine learning models. Tools such as AutoML have become increasingly popular because they do not require users to have statistical and ML expertise in the industrial environment and they reduce development costs by avoiding the need for high quality customized models. The adoption of these and other core knowlEdge technical elements addresses key user concerns and enables ML solutions to be produced without having to do unlimited research on data preparation, model selection, model hyperparameters and model compression parameters.

About the knowledge project

The knowlEdge project (Towards AI powered manufacturing services, processes, and products in an edge-to-cloud-knowledge continuum for humans [in-the-loop]) is European-funded project that started on 01 January 2021 and will end on 31 December 2023. The project is coordinated by VTT Technical Research Centre of Finland Ltd and brings together a consortium of 12 partners from 7 EU countries and 3 manufacturing domains: Barcelona Supercomputing Center (BSC), Bonfiglioli Slovakia s.r.o. (BSK), Centre for Research and Technology Hellas (CERTH), FernUniversität in Hagen (FUH), Information Catalyst for Enterprise (ICE), Fondazione LINKS- Leading Innovation & Knowledge for Society (LINKS), Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V. (FIT), Kautex Textron GmbH & CO KG (K-T), Nextworks (NXW), Parmalat S.p.A. (PARM), University of Münster (WWU), Universitat Poltècnica de Catalunya (UPC).

Figure 1. Conceptual comparison between current practices and the envisioned future following the knowlEdge project. See: S. Alvarez-Napagao et al., "knowlEdge Project –Concept, Methodology and Innovations for Artificial Intelligence in Industry 4.0," 2021 IEEE 19th International Conference on Industrial Informatics (INDIN), 2021, pp. 1-7, doi: 10.1109/INDIN45523.2021.9557410.